The Ultimate Guide to Organizing Your Tools with Customizable Foam Inserts

Introduction to Customizable Foam Inserts

Customizable foam inserts aren’t just foam. They’re your tools’ best buddies. Think of them as the ultimate organizers that turn chaos in your toolbox into a neatly ordered haven. Each piece of tool finds its own snug space, and there’s no more rummaging around, wasting time, or risking damage by having them clash against each other. Foam inserts come in different types, from soft pliable options to firm ones, offering various levels of protection and organization based on your needs. Whether you’re a DIY enthusiast with a penchant for woodworking or a professional mechanic, customizable foam inserts make your life easier. They can be cut and shaped to fit any tool, ensuring each one stays in place, remains easily accessible, and is protected from wear and tear. Plus, setting up your foam insert isn’t rocket science; with a bit of planning and some basic tools, you can create a perfectly organized toolset that fits your workflow like a glove.

The Importance of Organizing Your Tools

Having your tools organized isn’t just about making your workshop look neat; it’s about working smarter not harder. When tools are neatly arranged in customizable foam inserts, you save time searching for that wrench or screwdriver, which means more time actually getting things done. Plus, it’s easy to spot if a tool is missing, cutting down on the frustration of lost items. These foam inserts can be shaped to fit any tool, ensuring each one has its specific spot. This not only protects your tools from damage but also extends their life by preventing them from knocking against each other. Think about it, investing in organization is investing in the life and efficiency of your tools. So, yes, organizing your tools with customizable foam inserts is more than a convenience—it’s a smart choice for any craftsman who values their time and tools.

Different Types of Customizable Foam Inserts

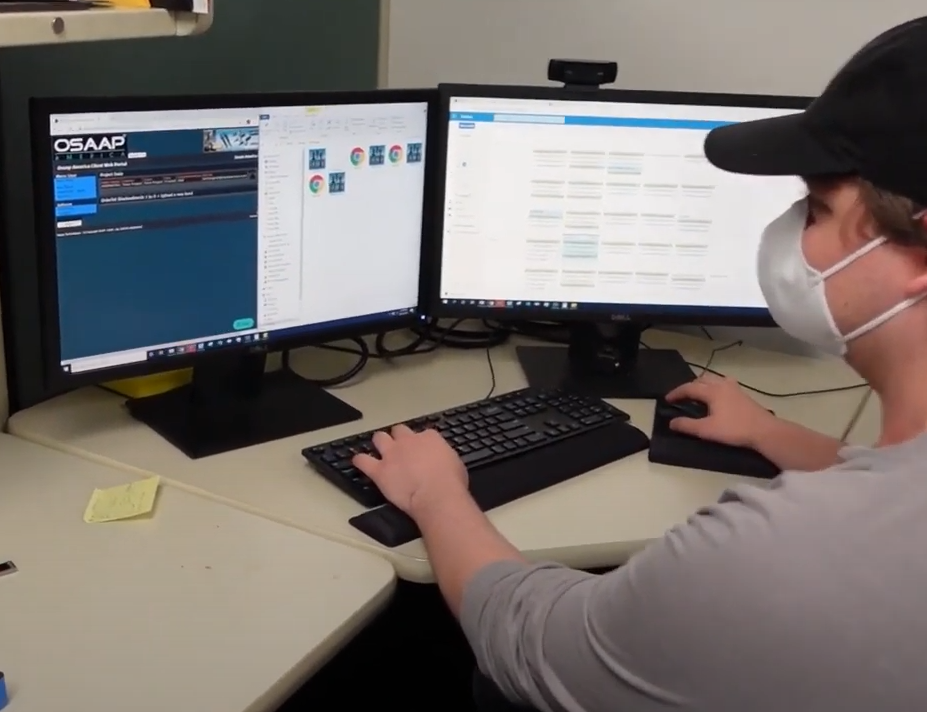

Customizable foam inserts come in various types, each designed to meet different needs and preferences. First up, we have pluck foam. This type is easy to customize. It comes as a solid block of foam with pre-scored cubes, allowing you to simply pluck out what you don’t need, creating a perfect spot for your tools. The down sides of the pick and pluck foam is its durability. Foam solutions like that of pick and pluck deteriorate fast and often rot from the inside once exposed to moisture or humidity. Next, there’s laser-cut or water-cut foam, which offers precision. You design your layout, and the foam is then laser cut to fit your tools exactly. It’s sleek and professional but can be pricier. The fault in laser or water cut foam is the lack of multi-depths. If you have a tool with multiple depths like a sledge hammer for example it is not going to fit just right. We do not recommend trying laser or water cutting on your own and recommend a professional service, like OSAAP, do the manufacturing for you. Trained technicians are recommended for these type of cutting machines. For those looking for versatility, sheet foam might just hit the mark. It’s a solid foam sheet you can cut by hand to fit your toolbox or drawer. This type requires a bit more effort but can be quite economical. Cutting sheet foam will likely require a lot of manual labor and hot-knife work. Lastly, CNC milled foam inserts are there for a custom fit. These are made by laying out sheets of foam on a CNC milling machine. When done by a professional, like OSAAP, these can be the perfect and the most professional solution for a customizable foam insert. CNC milled foam looks professional, depending on the material can last a lifetime, and offers the solution of multi-depth allowing for the perfect cutout to match your tool. Each type has its perks, depending on whether your priority is precision, flexibility, or cost.

How Custom Foam Inserts Protect Your Tools

Custom foam inserts aren’t just fancy padding; they’re like armor for your tools. Here’s the deal: Tools rattle around when you carry them, which can cause damage. Enter custom foam inserts. These guys snugly hold each tool, keeping them safe and sound. Think of it as giving your tools a personalized hug – each one sits perfectly in its designated spot, so there’s no movement, no scratches, and no premature wear and tear. It’s not only about preventing dings and scratches; it’s also about keeping your tools in tip-top shape for longer. Plus, it makes spotting if a tool is missing a breeze. No more guessing where you left that wrench; if there’s an empty spot, you know it’s time to track it down. In short, custom foam inserts save you money in the long run by protecting your investment and keeping your tools in action-ready condition.

Maintenance and Cleaning of Foam Inserts

Keeping your foam inserts clean and in good shape means they’ll last longer and protect your tools better. You don’t need fancy stuff to maintain them. First off, gently vacuum your foam inserts to get rid of dust and small particles. If they’re really dirty, mix some mild soap with water and use a soft brush or cloth to wipe them down. Make sure to rinse them well with clean water and let them dry completely before putting your tools back in. This avoids any moisture-related damage both to the foam and the tools. Avoid harsh chemicals or abrasive cleaners; they can break down the foam and ruin its protective qualities. Regular cleaning and maintenance not only extend the life of your foam inserts but also keep your tools in prime condition for your next project.

Now, if you want to avoid the hassle of cleaning you can choose a higher quality foam. OSAAP mainly stocks LD45, which is a cross-linked, close cell polyethylene foam which liquids/moisture cannot penetrate. This prevents foam rot and makes the foam easier to clean. Foam like this can be easily thrown in a parts cleaner or even a dishwasher. This foam is also strong enough to withstand most harsh chemicals and abrasives.

Conclusion: Streamlining Your Workspace with Customizable Foam Inserts

Wrapping it up, customizable foam inserts are a game-changer for anyone looking to streamline their workspace. They’re not just about keeping your tools in place; they’re about maximizing efficiency, reducing clutter, and keeping your tools safe. Think about it — no more wasted time searching for the right tool. Every tool has its spot, making your workspace smarter and your jobs faster. Plus, the protection foam inserts offer means your tools last longer, saving you money in the long run. Whether you’re a professional with a vast collection or a DIY enthusiast, customizable foam inserts adapt to your needs. Investing in them is investing in the order, safety, and productivity of your workspace. So, take the step. Organize smarter, work better.