Water Jetted Shadowboards

Introducing the OSAAP water jet for quick and clean manufacturing.

Water Jetting at OSAAP

A waterjet utilizes a high pressure stream of water to erode a narrow line in the stock material. Because the abrasive is added at the nozzle, it is simple to switch between water only and abrasive waterjet cutting. This flexibility greatly enhances the versatility of a waterjet machine, as it can easily switch from cutting ½” (1.27cm) foam gaskets to 4″ (10.16cm) titanium brackets.

The Water Jet at OSAAP Technologies is used for quick, clean, and strong shadow board creation. Our custom CAD software pairs perfectly with the water jet as we are able to develop designs and then machine them efficiently. Our current methodology involves foam on the water jet being cut through and then adhered to a plastic or foam thin bottom layer.

CHOOSING YOUR DESIGN

We offer water jetted foam in two different depths currently (15mm and 25mm) both sizes are available in 3 different colors: Blue, Red and Gray.

The base of the water jetted foam is adhered to the bottom of the designs. We offer 3 different types of base materials: foam, PVC and acrylic. Each base is available in 4 different colors: Blue, Red, Gray and Yellow.

Request a FREE Sample

Hold one of our shadowboards in your hands and feel the quality for yourself! Make sure to clarify what backing and base you would like to see on your sample.

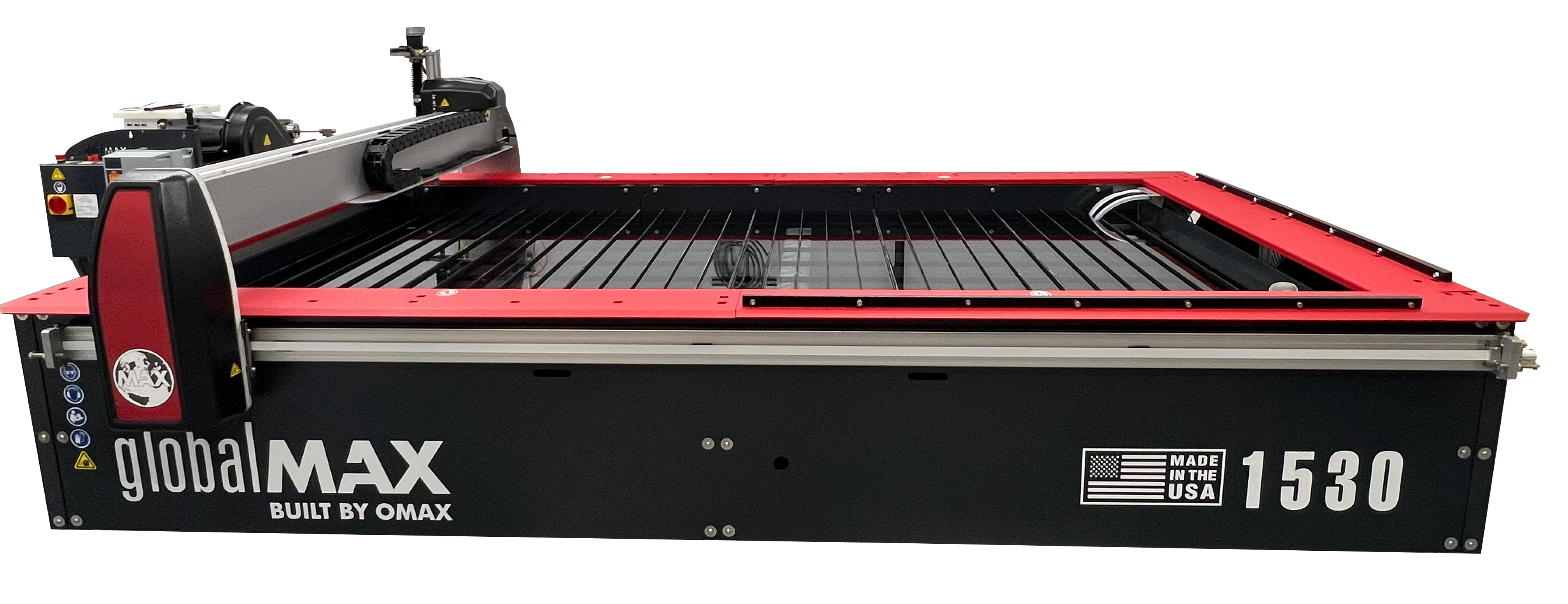

OMAX Water Jet

OMAX JetMachining Centers are designed to deliver high precision parts quickly and efficiently, maximizing productivity. Utilizing the most advanced computer control system available for abrasive waterjet machines, the OMAX JetMachining Center is accurate, versatile, and fast, machining everything from stainless steel to carbon fiber to glass.