Foam Inlays

It’s simple. Every tool needs its exact right place.

Exact Right Place

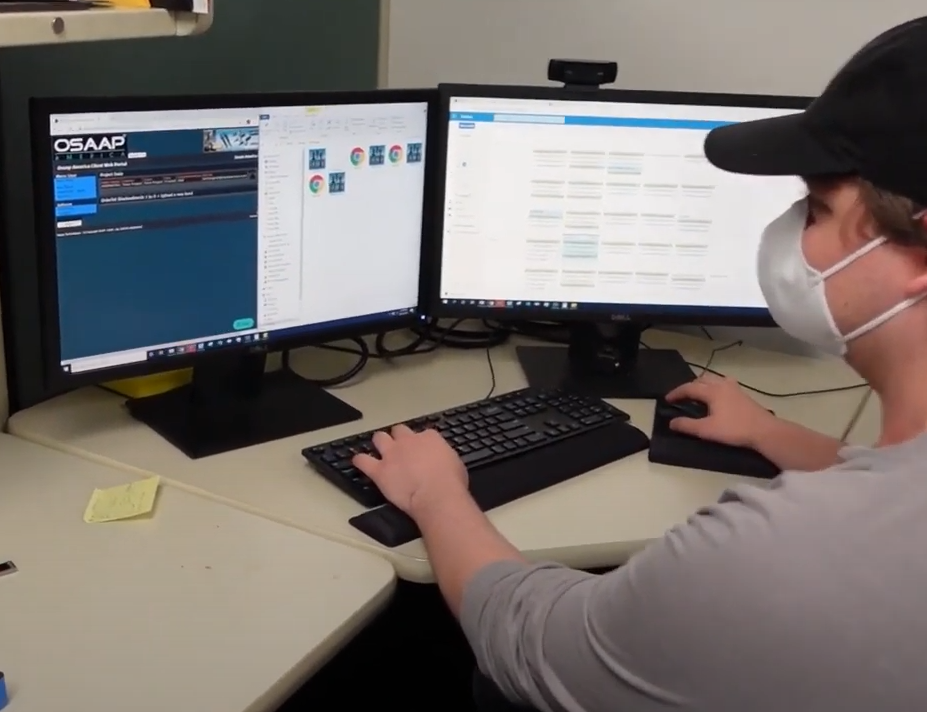

It’s simple. Every tool needs its exact right place. So, we make systems to organize those tools. We hear it time and time again. You have no design input, quotes take too long, production takes too long, it’s too expensive, and when you finally get your product, it’s not right. We’re here to bring order and cleanliness, to create a place for everything, and put everything in its place. Using our custom softwares, databases, and machines, we create a custom shadow board that is based on a quote you received automatically, based on your design input, based on weeks–not months–of production time, and based on our expert, reliable precision. With OSAAP, you’ll bring our German namesake to life–order and cleanliness in your workplace.

Kitting Process

Our kitting process is simple, as we can custom fit our foam inlays to any application. You pick out the case you want and the tools you need, and we will do the rest. Scanning your tools into our custom CAD software can be done in many ways. We offer multiple tool-scanning options, including both 2D and 3D systems, that will capture an image of your tools for us to upload. For smaller projects, we also offer the option to simply trace your tools and send us the document; once scanned, we can upload your tools to our software and begin design.

Quick Turn Around

Once your design is complete, you will receive your complete manufactured kit within a month. Here at OSAAP, we work with our customers throughout their entire design process, whether it be providing guidance in designing their own board, or designing the board for them, through a collaborative communication process. Every design is different and exciting, and our goal is to create designs that you are proud of.