Lot Size of One

Manufacture one unique board as efficiently as others manufacture a thousand

Low Volume High Mix

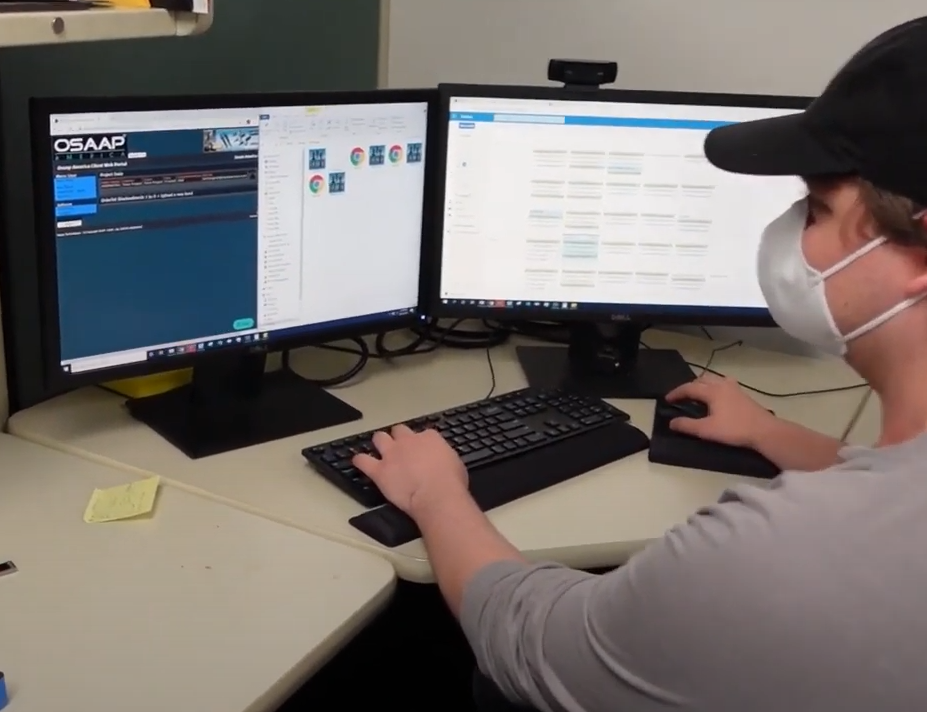

Our goal over the past decade at OSAAP has been to develop a process that allows each mechanic to organize their tool drawer to their specific needs, simply and efficiently. We want you to be able to purchase one unique tool insert, designed for your unique needs, at a comparable price to the standard insert in a catalog or online.

Industrial Manufacturing

Industrial manufacturing often requires tool inserts for LEAN and 5S projects in low volumes of 5 or 10 boards. The design traceability built into Blue Manager enables Manufacturing Engineers to update the tool inserts as the workflow changes quickly. You can quickly look back at the tool insert design history, process updates within your account, and order updates seamlessly.

Aircraft Manufacturing

FOD control is a critical part of aircraft and aerospace manufacturing. Every tool used in the manufacturing process needs to be identified before an aircraft engine or rocket can move from one step of the assembly operation to the next. Every part used in the assembly of the aircraft or rocket needs to be safely stored and accounted for. Each tool and part used is unique and requires it’s own unique storage location. OSAAP’s process enables aircraft and aerospace manufacturing facilities to scan tools and import 3D files into simple CAD software, to lay out unique foam and plastic shadow board inlays. The designs are managed in a project database with full backward traceability. The shadow board inlays can be ordered through OSAAP, or manufacturers can bring the OSAAP process in-house and manufacture on-site. ITAR facilities can work disconnected from the internet and convert designs on-site to NC Code for milling on the OSAAP Blue Mill.

Get in touch

Our team looks forward to hearing from you. Please contact us for information about your application needs.

More Process

Order and Cleanliness at the Workplace