Products

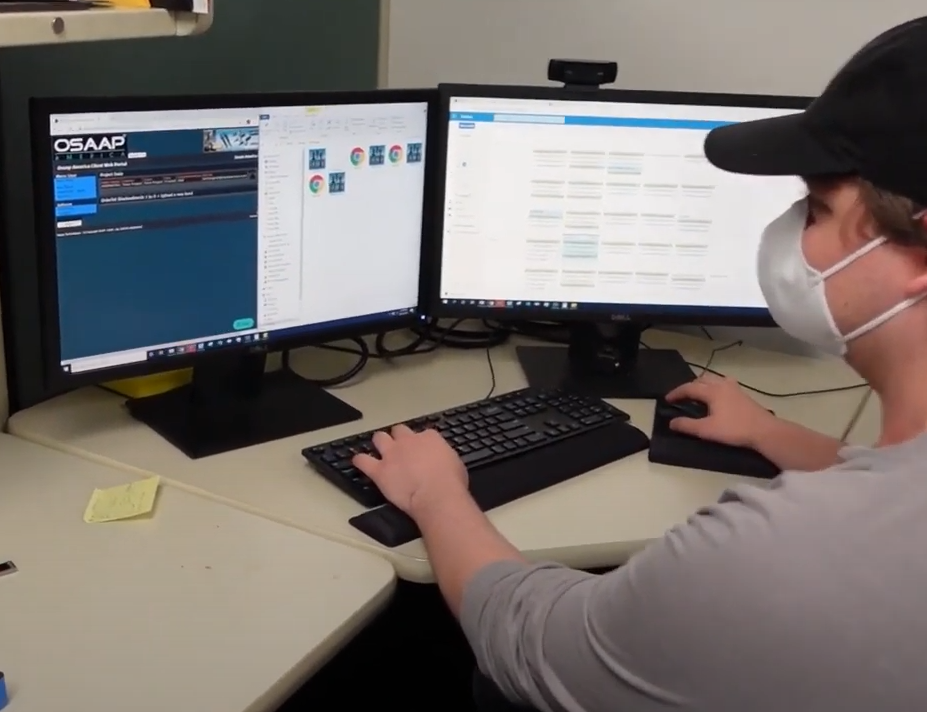

OSAAP has developed a closed-loop space for our customers to work in. Once you are in our space, you have everything you need to design, manage projects, and manufacture foam and plastic shadow boards, inlays, fixtures, and full kits.

Our Process

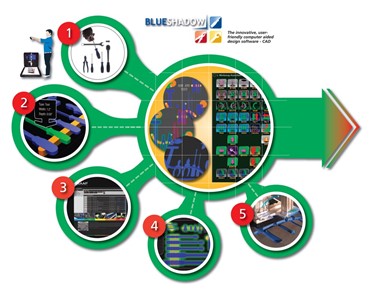

For over a decade, OSAAP has been creating unique solutions, specifically for the process of making shadow boards, inlays, fixtures, and full kits. Our entire process, including CAD software, imaging solutions, scaling software, project database, manufacturing software, laser and milling machines, is all done completely in-house.

Shadow Boards

Shadow Boards are storage boards for tools, supplies or equipment, used in manufacturing and service environments. A shadow board is an organized workplace where tools, supplies and equipment are stored in appropriate locations, close to the work area or maintenance location. It is a simple and inexpensive storage solution, which provides tangible efficiencies and cost savings.

The primary advantage of using shadow boards is the elimination of wasted time and money. By providing the ability to quickly guage the location of tools and equipment, or determine if anything is missing, there is no time wasted searching for the appropriate tool, or interchanging tools between tasks. Shadow boards are used in the sort and set order stages of the implementation and operation of a 5S System in a workplace.

Shadow boards can be different sizes and located in many different areas of a process or plant. The key is that they are appropriately located and hold all the necessary tools for the area or workstation.

Foam Shadowboards

OSAAP stocks 2.8#/ft3 density (45 Kg/m3) closed-cell, cross-linked, and inert foam, for fast delivery of the highest quality product for industrial applications.

Plastic Shadowboards

OSAAP stocks high-density polyethylene sheets with multiple layers of contrasting colors, for fast delivery. Plastic is best used for FOD-free applications in clean rooms, medical facilities, and the food industry.

Scanning

OSAAP offers simple, proven solutions to get models of your tools and parts into a workable design.

Manufacturing

We only sell the machines we have developed and use in production every day, ensuring a fulling vetted and supportable product.