Workflow

Workflow

We’re a custom fit, full-solution process. And we go beyond all requirements to make the custom tool inserts that will work for you. For every project, every time. No matter what equipment you have, expect the highest quality–and not to mention, fastest–shadow boards through our proven, precise process. But that doesn’t mean we’re not collaborative. Within our customer interface each client is involved in each step of the process as they choose to be–from taking perfect photos of their tools to the design process in our easy-to-use custom CAD software, to day one of production, your project is under control. And we mean precision-control. We generate instant unique NC codes to create a shadow board of any size with any combination. Best of all, we rely on state-of-the-art manufacturing processes paired with our proprietary software–creating the perfect space for each individual tool.

Visit our knowledge base for tutorials on our processes and software.

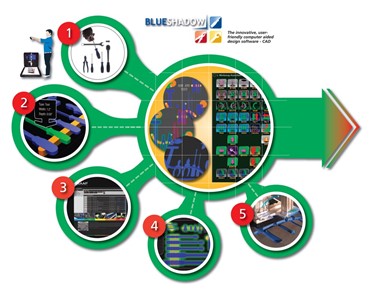

Step 1: Image

We can import your CAD files, 1:1 tracing, 2D images taken on our light panel system, or 3D images developed using the Obi3 Scanning system. See the process detail pages for in-depth information on each process.

Step 2: Design

Blue Shadow is a very user-friendly CAD software that we have developed specifically to design shadowboards and inlays for cases. You can download Blue Shadow for FREE and get started designing your board.

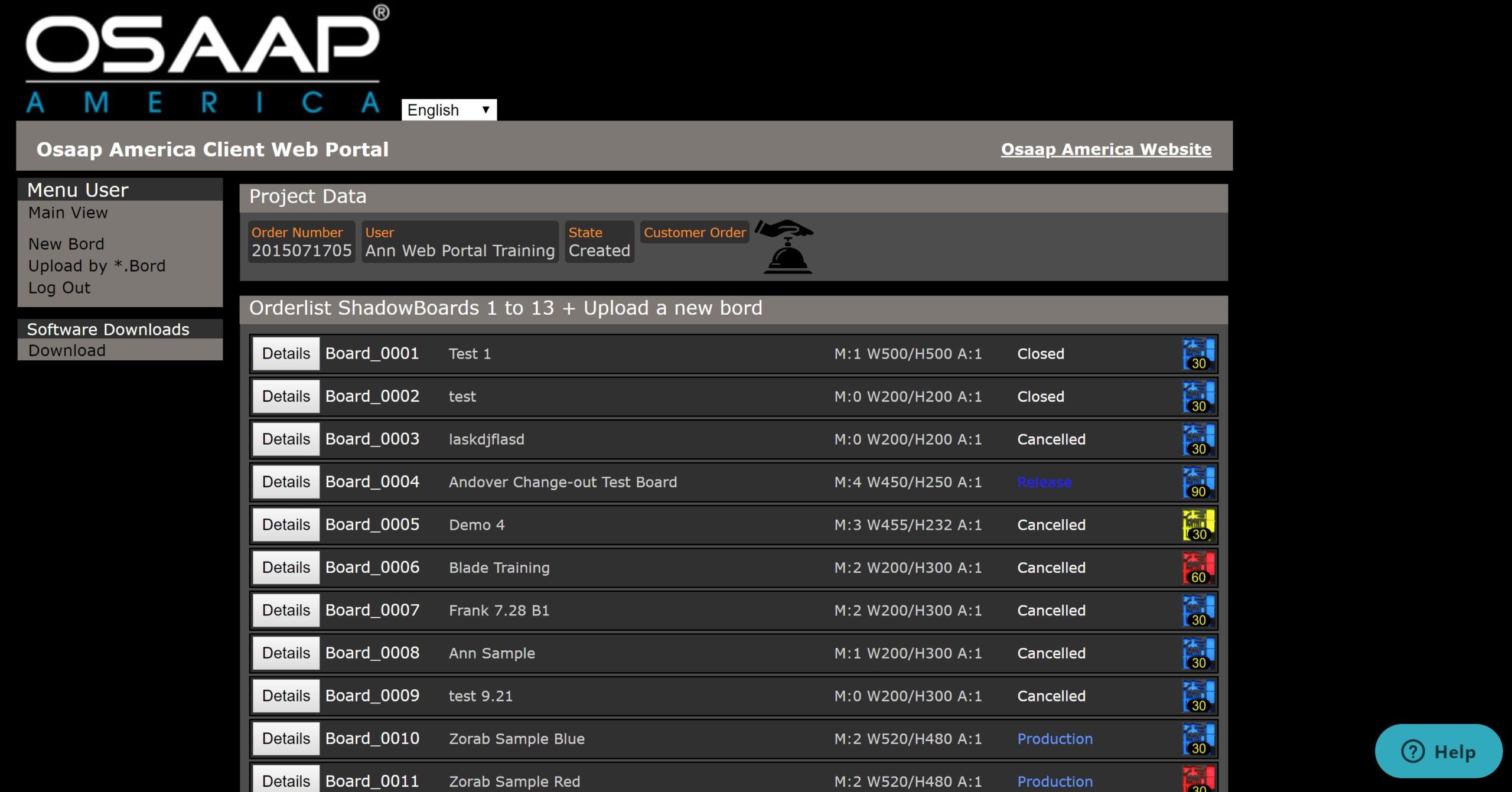

Step 3: Web Portal

Obtain a new project web portal from OSAAP. The portal contains all the information for your project, with each board collated for individual management. Once your images are uploaded to a project portal, we will start your design for FREE. With the combination of our Blue Shadow software and our design support, you can interface with your projects at the level that fits your schedule without delaying the workflow.

Step 4: Edits & Approval

Whether you upload a completed design or only images and we design for you, we send an email notification after our review is completed. Upon login you will find an approval pdf, help photos, your completed design and all your revision history for traceability.

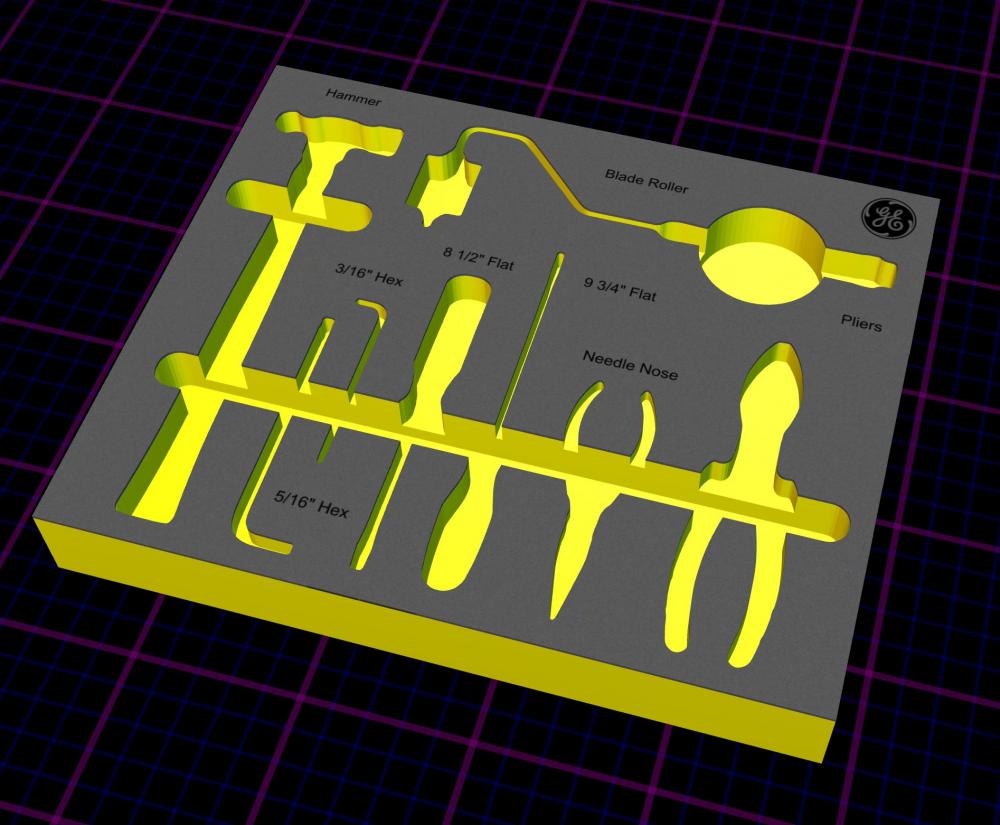

Step 5: Mill and Laser Etching

The manufacturing side of our process is equally as automated as the design side, enabling us to manufacture a single board just as efficiently as multiple boards.

Laser: We can incorporate your logo onto our foam shadow board design and laser/drill mark your custom text into your board with ease

More Processes

Order and Cleanliness at the Workplace